|

| This is the clock movement bench where the

movement is photographed, inspected, repaired,

and reassembled. The computer displays reference

information, images of the movement, and a

"sound graph" of the amplified ticking

to verify that the finished movement is in

beat. |

|

| All parts are carefully checked for proper

fit. Excessively worn pivot holes are reamed out

and precision bushings installed to ensure proper

operation and long life. |

|

| Each part of a disassembled clock movement is

carefully inspected and hand cleaned [above] in

one or several cleaning solutions as appropriate

for that movement, or ultrasonically cleaned

[below], or a combination both. |

|

| Parts undergoing ultrasonic cleaning in a

special clock cleaning solution. |

|

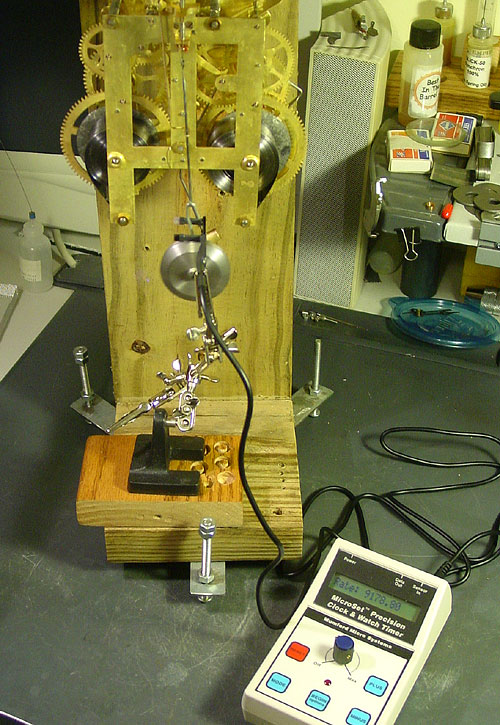

| A reassembled clock movement is

electronically calibrated to ensure that it is

"in beat" and will keep time when

reinstalled in the clock case. |

|

| Across the room is this bench where case

repair and other less clean operations are

performed. |

|

| This small lathe sees a lot of use in turning

and polishing rough and worn clock pivots, as

well as fabricating special parts and

tools..... |

|

| .....and for the big jobs, this old 9-inch

South Bend from the 1920s can still get the job

done! |

|

| This level wall shelf is one of several

locations where a finish clock is allowed to run

for a couple of weeks to facilitate final testing

and regulating before being returned to the

customer. |

|

| This strange looking contraption is a custom

made test rack that can support a variety of

clock movements, including weight powered

movements and complete cuckoo clocks. Undergoing

a test run when this picture was taken is a

weight powered wooden movement from the

1830s.

|

|